The main difference between static and dynamic balancing is the way in which the balance weight is placed on the wheel.

Static balancing uses weights that are fixed on the rim of a wheel, while dynamic balancing uses weights that move around (or oscillate) as you spin the wheel. The reason why it’s called “dynamic” balancing is because it takes into account the centrifugal force generated by spinning wheels. This means that the balance weight needs to be placed in different positions depending on whether your wheels are rotating or not.

Below are static & dynamic balancing differences:

Static Balancing

In static balancing, you mount your weights directly onto the rim of your wheel (usually with a special adhesive). These weights usually come in pairs — one for each side of your tire — and are evenly spaced out at 90-degree angles from each other. When properly installed, these weights should be able to distribute themselves evenly across the entire surface area of your rim so that they don’t cause any unwanted vibrations during acceleration or braking.

Dynamic Balancing

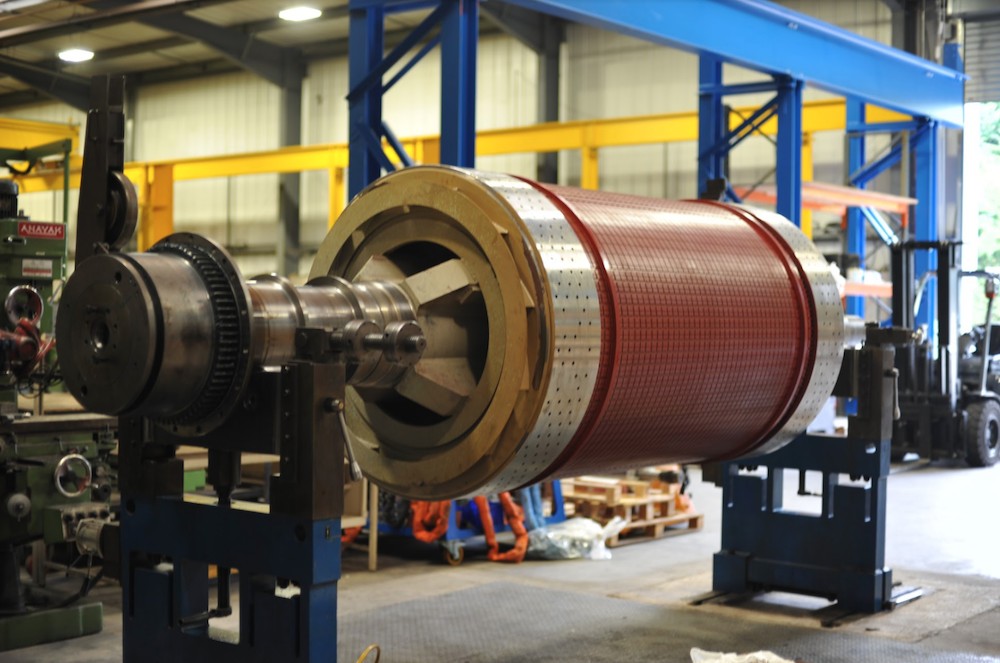

In dynamic balancing, the weights are moved back and forth along the shaft to find their optimum locations. This can be done manually or automatically using computer-controlled equipment. Once this has been done, it is necessary to reattach these weights permanently onto the shaft so that they stay in place during operation of the machine. Dynamic balancing can be applied to multi-rotor machines (machines with more than one shaft) as well as single-rotor machines.

There are two types of balancing that can be done on a shaft: static and dynamic. Static balancing is performed by attaching weights to the shaft at strategic points, while dynamic balancing is performed by attaching the weights to a spinning shaft.

In static balancing, weights are attached to the shaft in order to balance it out. These weights are added strategically so that they are evenly distributed around the length of the shaft. The amount of weight needed depends on how much force will be applied to it, how long it will be used for, and what kind of material it’s made from.

In dynamic balancing, weights are attached to a spinning shaft so that it continues to spin smoothly even when under pressure from external forces such as gravity or impacts from other objects. This is done by placing weight in strategic locations along the length of the shaft so that they counterbalance each other out when they spin at different speeds due to different amounts of torque being applied at different points along its length.

Static balancing is the process of balancing an engine without any load. It is used for testing balance and setting tolerances before installing the engine into the vehicle.

Dynamic balancing is the process of balancing an engine with its load on it. This can be done with a dyno or on the vehicle.

Static Balancing is done on a wheel balancer, which has two platforms separated by a spring-loaded center cone. The wheel is placed on top of this spring loaded center cone with weights added to one side until it becomes balanced. This method allows for easy measurement and recording of weight distribution to ensure that each wheel is balanced equally with respect to each other.

Dynamic Balancing can be performed either on the vehicle or in a dyno cell but requires more sophisticated equipment than static balancing (i.e., computer controlled dynamic balancers).